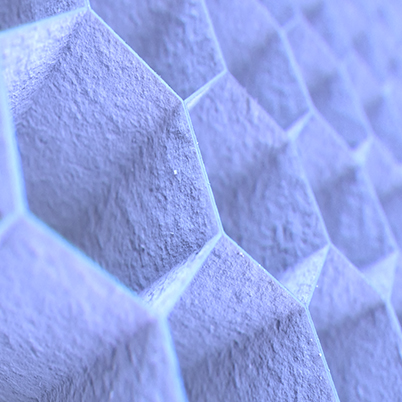

The Calistair Technology describes a modular reactor, that can be integrated or retrofitted in any ventilation and air-conditioning system or in a unit for cleaning the air. It is based on honeycomb structures impregnated with a chemical substance, which are fitted in a metal frame and are activated by UVC lamps.

The air disinfection achieved makes a valuable contribution to the protection of human health. This is not the only thing that makes the technology the pioneering solution: The reactor is available in any sizes and formats, making it the solution for diverse contamination problems. The fact that several reactors can be laid out in sequence, next to each other or on top each other, makes use of the Calistair Technology virtually universal. It improves the quality of the end products and industrial goods you produce and therefore makes the world a bit safer.

The chemical bonds of the pollutants are activated after direct contact with the catalyst and are highly reactive. The radicals have a life of only a few picoseconds, which is long enough to trigger a destructive chain reaction. This oxidation reduction breaks up the structure of the pollutants. The result: depending on whether the pollutants are gaseous or microbiological – they are neutralised and mineralised. The non-thermal catalyst ensures that neither pollutants nor toxins such as ozone or other by-products are released during the destruction. It is only the clever combination of the catalysts that ensures that only safe products such as water and CO2 are produced in tiny quantities.

Summarising, it can be determined that all substances that reach the surface of the catalysts are re-released in another form. The catalysts regenerate themselves after the process – which makes them a versatilely usable solution for air decontamination in your company too.

This aspect is underscored still further by another fact: our technology can process large quantities of air with a velocity of up to 5 m/s for air decontamination. This makes it so flexible across multiple industries and business sectors.

The easy maintenance, the environmentally friendly and energy-efficient operation and the lack of any ozone concentration make Calistair a solution for more air cleanliness with virtually no alternative. In your company too.